Not every LED screen fits the same mold—and that's exactly what today's buyers are asking for. In recent years, more clients are walking in with specific ideas: “I need this to wrap around a column,” or “Can it handle 24/7 outdoor exposure in the summer heat?” The market has shifted. Standard products aren't always enough.

Custom Projects Are Now the Norm, Not the Exception

For a long time, manufacturers offered fixed options: a few sizes, standard pixel pitches, and that was it. Now things are different. A retail brand might want a curved screen that wraps around their shopfront. A stadium might need seamless displays across uneven structures. These aren’t rare requests anymore—they’re daily business.

Factories that serve the LED display market have noticed this change and started adjusting how they work. It’s no longer about just producing units—it's about listening to the space, the usage, and the visual goals, then building around them.

What Kind of Customization Are Buyers Looking For?

Most customization requests fall into three buckets:

-

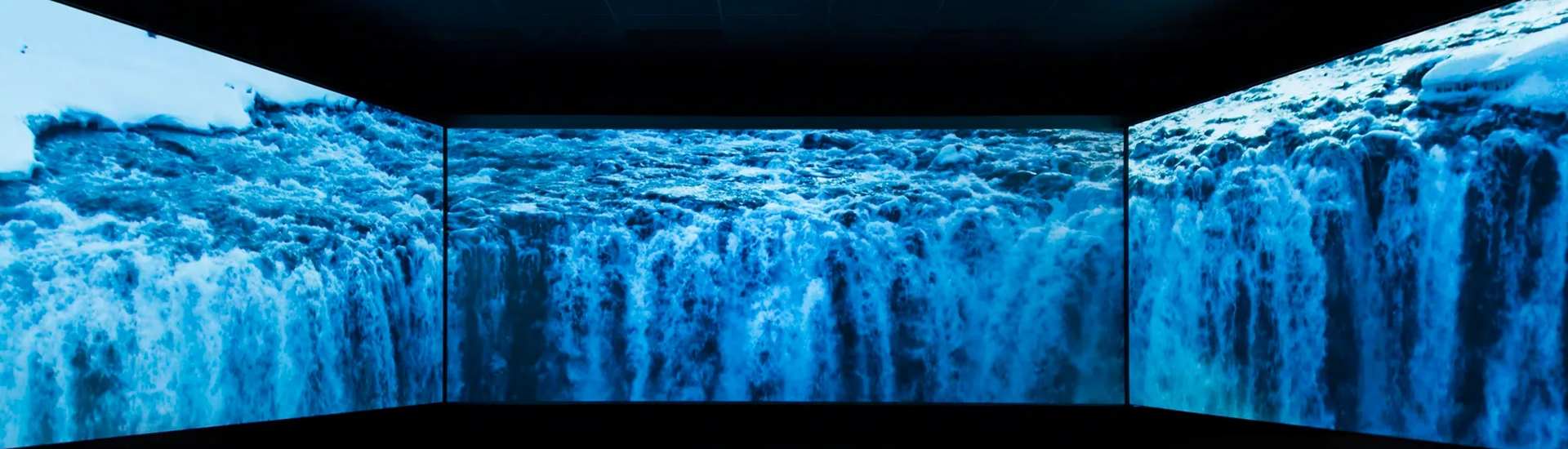

Size and shape: Some clients need ultra-wide, some need tiny modules. Curved, L-shaped, edge-wrapped—these shapes now appear regularly in design briefs.

-

Performance and environment: Brightness matters. So does weather resistance. An outdoor LED display in Dubai needs a very different setup from an indoor screen in a museum.

-

Visual integration: It's not always about standing out. Some customers want the LED display to blend into the architecture or match a specific color theme. That might mean a custom housing, special frame colors, or seamless panel borders.

How Manufacturers Make It Work

This kind of flexibility requires more than just design tweaks. Manufacturers have had to change the way they plan production, keep inventory, and work with clients. Modular panels help a lot—they can be arranged in many ways and make it easier to match different dimensions without starting from scratch every time.

Some manufacturers now keep key components on standby, ready to be configured into a custom unit. Others build dedicated teams to handle unique orders, combining R&D and production to make sure everything works by the time it's shipped.

It’s Not Just About Hardware

A screen that looks great but is hard to maintain isn’t a good investment. Customization often includes backend support: easier access for repairs, simplified control systems, and installation kits designed for non-standard mounting.

Installers and clients are asking: “How quickly can I get replacement modules if something goes wrong?” That means suppliers need to think long-term, not just about delivery, but ongoing support as well.